Chemical, oil and gas

Chemical, oil and gas

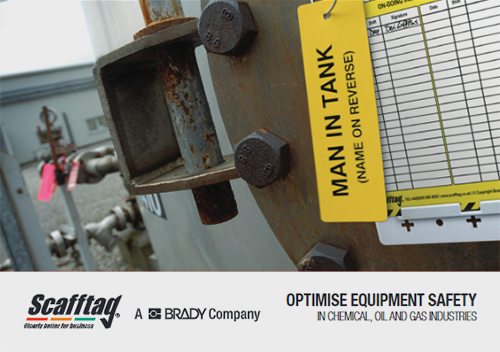

Optimise equipment safety in chemical, oil and gas

Hazardous equipment, mission-critical processes and equipment-intensive operations are just a few of the unique challenges and safety risks facing today’s chemical, oil and gas industries. Whether you are a part of a chemical processing facility, petroleum refinery, drilling rig or tank terminal, it is vitally important to maintain a safe, compliant and visually instructive work environment.

Visual Tagging solutions help companies to keep track of inspections and communicate inspection results and/or process management & control on the equipment itself with all employees. The solution supports compliance with EU Directives and can further increase workplace safety and efficiency by avoiding the use of uninspected equipment

Comply with equipment safety regulations

With Visual Tagging solutions, you can supportcompliance with laws and regulations aimed at improving workplace safety.

- European Directive 2009/104/EC The employer shall ensure that the work equipment is installed correctly and is operating properly by inspection/testing of the work equipment (initial, after assembly, periodic and special) by competent persons. The results of the inspections shall be recorded and kept.

- UK PUWER Regulations 1998 (Provision and Use of Work Equipment) The result of the inspection should be recorded and this record should be kept at least until the next inspection of that equipment.

Visual tagging solutions for chemical, oil and gas industry

Visual Tagging solutions can be used to uniquely identify a wide range of tools and equipment. They can communicate the latest equipment inspection and status at the point of use and record an audit trail of equipment maintenance, tests and inspections to comply with health and safety legislation. They can also communicate work equipment process management & control on the work floor.

Visual Tagging solutions typically include two components:

Holder

Displays a ‘Do not use’ warning message and is available in a variety of shapes to fit a wide range of tools and equipment.

Holders can be mounted tightly to any equipment. They are made out of UV-stabilised ABS or Nylon 6 and provide good flexibility and elasticity to avoid breaking

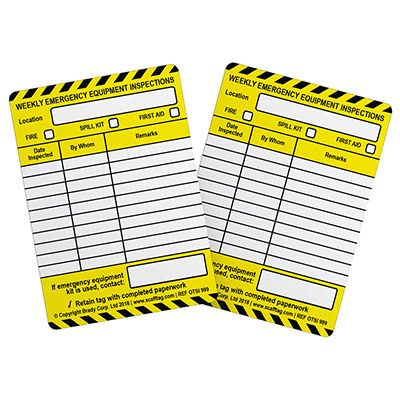

Insert

Communicates best practice inspection information as well as well as inspection records and planning. When equipment fails inspection, the insert is removed, leaving the clear ‘Do not use’ message.

Inserts will not tear or break and can easily be written on with a permanent marker pen. They are made out of UV-stabilised polypropylene that can easily be wiped clean without smudging the text.

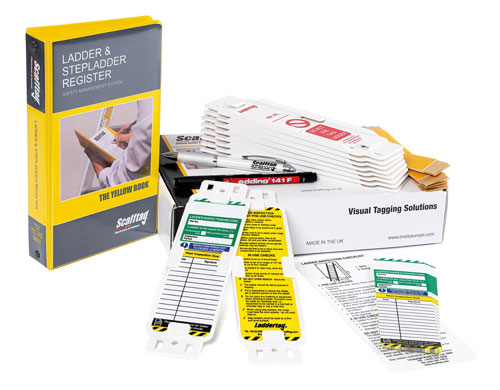

Customize your visual tags

Visual Tagging solutions are highly customizable and can be applied to a wide range of equipment in order to improve inspection quality and equipment safety communication. The holders and inserts are very reliable and can withstand harsh environments, including chemical, oil and gas sites.

Whatever your equipment, we can tag it. We can custom design Visual Tagging Solutions

to help you manage virtually any issue and fit seamlessly with your business and systems. A

wide range of customisation options are available including:

Tag size and shape

- Data to be displayed/recorded

- Visual design including logo, colours and fonts to reflect corporate branding

- Adaptation to specific site requirements like adding metal strips for magnetic detection in food plants

- Attachment method variation e.g. cable ties, split ring, magnetic, adhesive

Visualise equipment processes with our products

Visual Tagging solutions are highly customizable and can be applied to a wide range of equipment in order to improve inspection quality and equipment safety communication. The holders and inserts are very reliable and can withstand harsh environments, including chemical, oil and gas sites.

Highly efficient equipment inspections

Every Visual Tagging holder and or insert can include best practice inspection procedures on the equipment that needs inspection. Both the holders and removable inserts are highly customisable and can support the standardisationof evolving equipment inspection procedures. A QR code can also be printed on the inserts or holders to activate a digital inspection flow via smartphones and Safetrak software, complete with inspection planning management and automatic inspection report generation.

Get Best Support for Maintenance Inspection Tags & Workplace Safety