Pipeline identification advice

How to setup a proper pipeline identification system?

Unmarked pipes are a danger to both life and property. Accidents, injuries and damage to equipment can be caused by people not knowing what individual pipes contain. Unmarked pipes can also create wasted time information searching for pipe contents, especially for temporary contractors or new employees.

The Health and Safety (Safety Signs & Signals) Regulations 1996 require employers to mark visible pipes in the workplace which contain or transport dangerous substances.

Our recommended actions:

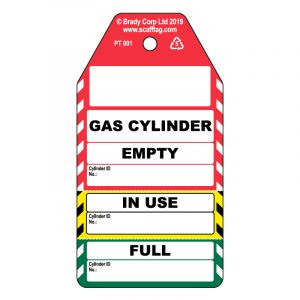

Piping identification systems, such as tags and inserts, play a critical role in ensuring safety in the workplace by providing vital information about the contents, pressure, and flow of a pipe at the point of use. This information is crucial for workers to understand the hazards associated with a particular pipe and to take the necessary precautions to avoid accidents.

For example, if a pipe is not properly labeled, a worker may unknowingly open a valve or make a connection that releases hazardous material, leading to injury or illness. Furthermore, if a pipe is not properly identified, it can be difficult to locate and repair in the event of a leak or malfunction, resulting in lost man hours, production downtime, and equipment damage or loss.

In addition, OSHA regulations require that pipes be properly identified to ensure that workers are aware of the potential hazards associated with a pipe, and to provide them with the information they need to work safely. Failure to comply with OSHA regulations can result in significant fines and penalties.

Correctly identifying pipes ensures this vital information is available at the point of use which in turn can reduce:

- Accidents and lost man hours

- Production downtime

- Equipment damage and loss