How to use Visual Tags

Safety. Maintenance. Identification.

Think about any item of equipment on your site:

- How do you know it is fit for use?

- When was it last inspected?

- How do you identify it among the hundreds of similar items?

Without the latest information, people are prone to make assumptions. Assumptions can lead to potentially damaging decisions for both them and your business. The identity, maintenance and inspection status of equipment is therefore critical.

What are visual tags?

Visual tags help:

- Communicate the latest equipment inspection and test status clearly at the point of use

- Record an audit trail of recent equipment maintenance, tests and inspections

- Uniquely identify equipment

- Comply with Health and Safety Legislation

- Reduce accidents in the work place

We can help you with Visual Tagging for Work at Height, Plant, Vehicles, Machinery & Tools, Workspace Control and Process & Pipelines.

In fact! Whatever your equipment – we can tag it!

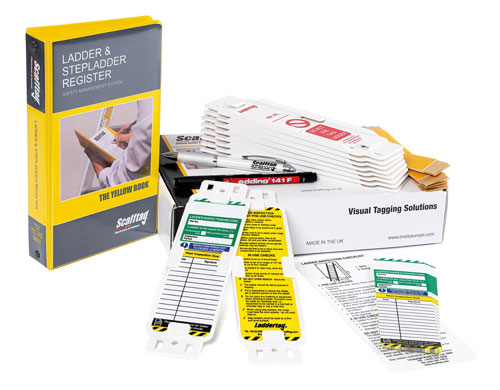

Holder and Insert System

Our visual tags typically comprise of two components a holder and an insert which work together in a looped process.

- Holder Attaches to the equipment being tagged.

- Insert Placed in the holder and used to record and display the latest equipment status.

1. Attach: The empty holder displays ‘DO NOT USE...’ symbol and is attached to equipment

2. Inspect: Equipment is inspected periodically, as deemed appropriate by risk assessment, and the results recorded on the insert.

3. Insert: If the equipment passes inspection then the insert is placed in the holder, displaying the latest equipment information to any users.

If equipment fails inspection at any point, then simply remove the insert from the holder to display the ‘DO NOT USE...’ sign.

Get Best Support for Maintenance Inspection Tags & Workplace Safety